How does fast paper become an ideal new material choice with its excellent mechanical strength and toughness?

Release Time : 2025-06-30

As a new material, fast paper has shown excellent performance in many application scenarios with its excellent mechanical strength and toughness, making it an ideal new material choice. This material is not only widely used in new energy product accessories and automotive interior parts, but also shows its unique advantages in many other fields. From high strength to good toughness, to excellent electrical insulation performance, fast paper provides a full range of solutions for modern industry.

First of all, fast paper has excellent mechanical strength, which enables it to maintain structural integrity and functionality in various harsh environments. Whether it is used to manufacture parts that need to withstand large loads or as a protective layer, fast paper can provide sufficient support to ensure long-term stable operation of equipment. For example, in the power system of new energy vehicles, fast paper can be used to make the protective shell of the battery pack, effectively resisting external impact and preventing damage to internal components. At the same time, the high strength characteristics of fast paper also make it suitable for manufacturing structural parts that require high load-bearing capacity, such as brackets, frames, etc. These applications not only improve the durability of the product, but also extend the service life of the equipment and reduce maintenance costs.

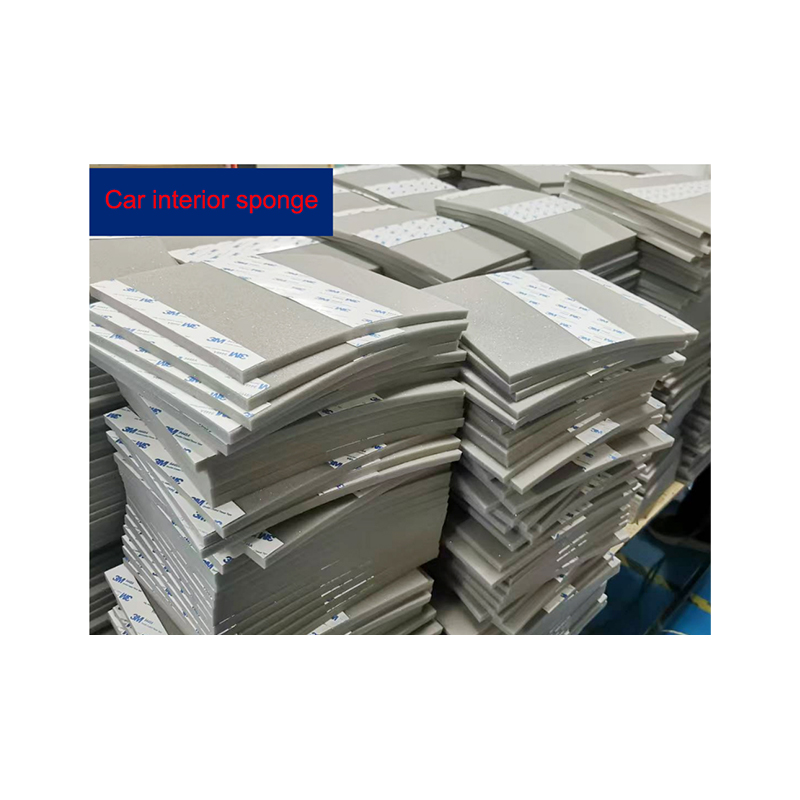

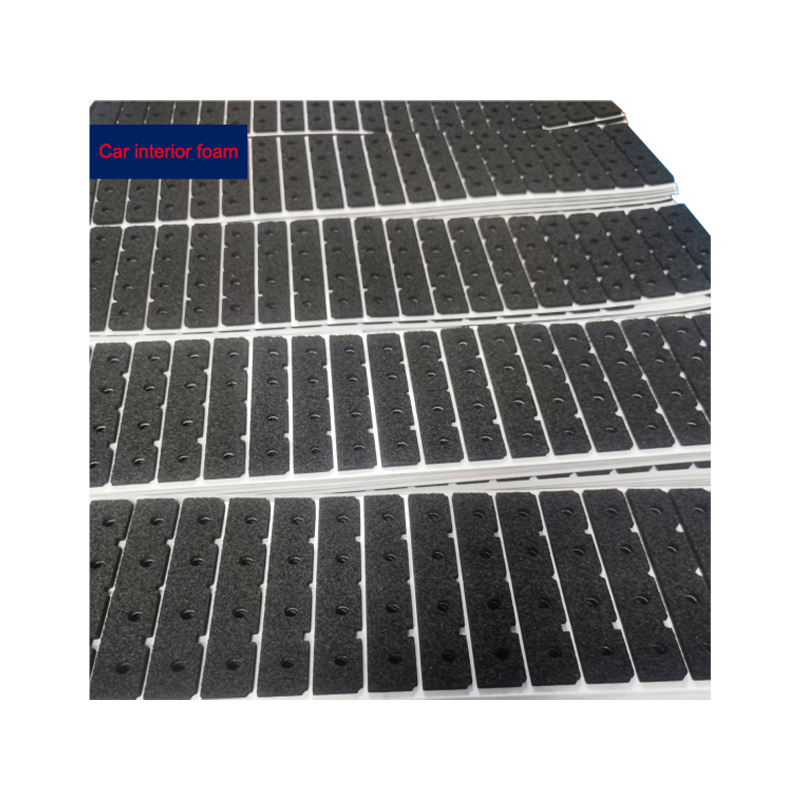

Secondly, the toughness of fast paper is also remarkable. Compared with traditional materials, fast paper has better tear resistance and is not easily broken or damaged by external forces. This feature is particularly suitable for applications that require frequent bending or folding. For example, in the design of automotive interior parts, fast paper can be used to make seat backs, dashboard covers and other parts, which not only ensures aesthetics but also improves user experience. In addition, fast paper has a large transverse elongation, which means that it can evenly distribute stress when stretched and avoid damage caused by local concentrated stress. This feature is particularly important for components that need to work in a dynamic environment because it can effectively reduce the risk of failure caused by fatigue damage.

Furthermore, the mechanical properties of fast paper are not only reflected in strength and toughness. Its longitudinal strength is greater than the transverse strength, which also provides optimization solutions for specific applications. In some cases, the material is required to have higher rigidity in one direction and a certain degree of flexibility in another direction. Fast paper just meets this demand. Through reasonable design, the material can perform optimally in different directions. For example, when manufacturing composite materials that require directional reinforcement, the anisotropic characteristics of fast paper can significantly improve the load-bearing capacity and stability of the overall structure without adding extra weight.

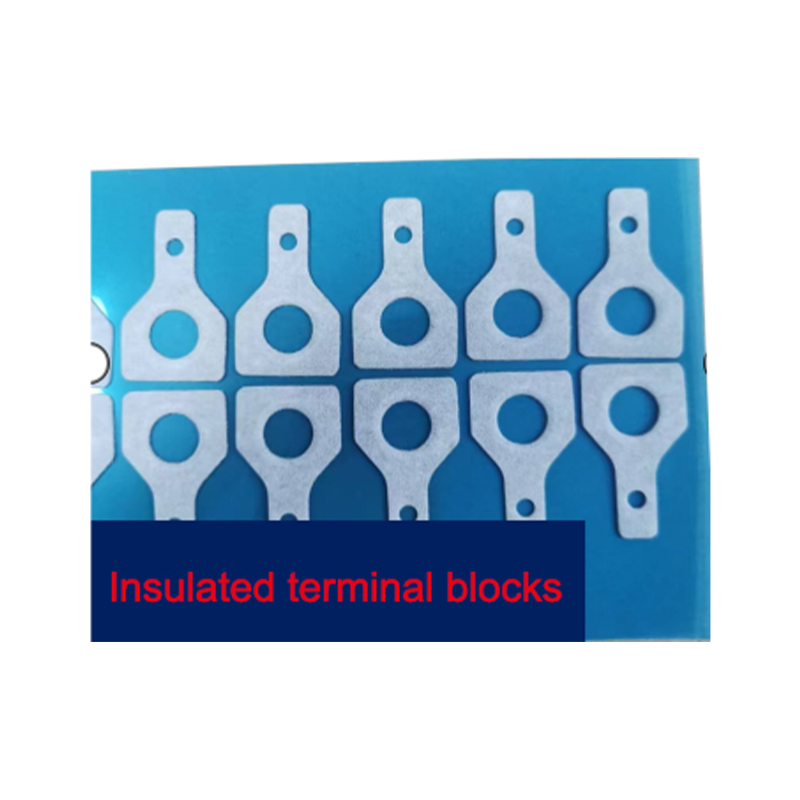

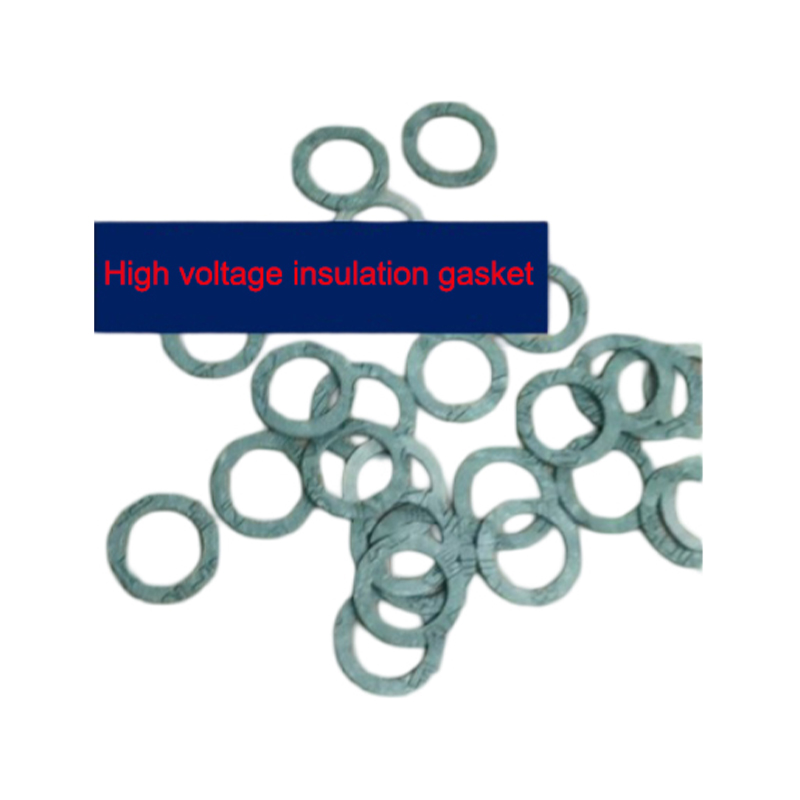

Not only that, fast paper also has good electrical insulation properties, which further enhances its application potential in the field of electrical safety. As electronic equipment becomes increasingly complex, the requirements for electrical insulation of materials are also getting higher and higher. Fast paper can not only effectively isolate current, but also prevent the potential dangers caused by static electricity accumulation. This is crucial to ensure the safety of operators and protect sensitive electronic components from damage. In the high-voltage circuit system of high-voltage electrical equipment and new energy vehicles, fast paper is widely used to manufacture key components such as insulating gaskets and partitions to ensure the electrical safety of the entire system.

In addition, the heat resistance of fast paper is also a highlight. In high-temperature environments, many traditional materials may soften, deform or even fail, while fast paper can maintain stable physical and chemical properties under extreme temperature conditions. This makes it very suitable for manufacturing components that need to be exposed to high temperature environments for a long time, such as heat shields in engine compartments and protective layers around exhaust pipes. In addition, fast paper also has excellent arc resistance and tracking resistance. These characteristics work together to ensure that the material can still work reliably when facing high voltage and strong current, greatly improving the safety of electrical systems.

It is worth mentioning that fast paper also performs well in environmental protection. As a recyclable material, fast paper has a low impact on the environment throughout its life cycle. With the increasing global attention to sustainable development, more and more companies are looking for green materials to replace traditional non-degradable or hazardous substances. The emergence of fast paper provides companies with an option that can meet high-performance requirements while taking into account environmental protection, helping to promote the industry to a greener and low-carbon direction.

Finally, in practical applications, fast paper has been widely recognized for its excellent comprehensive performance. Whether in the field of new energy or the automotive manufacturing industry, this material can provide reliable performance support. It not only improves the quality and reliability of products, but also helps companies achieve the goal of energy conservation and emission reduction. For companies pursuing efficient and environmentally friendly production methods, choosing high-quality fast paper is undoubtedly one of the best choices.

In summary, fast paper has become an ideal new material choice with its excellent mechanical strength and toughness. From high strength to good toughness, to excellent electrical insulation performance, every detail provides users with a more reliable, efficient and environmentally friendly solution. With the advancement and development of technology, fast paper in the future will continue to take solid steps in improving product performance and ensuring safe production, bringing more innovative solutions to various industries. In this process, continuous attention to user needs and technological innovation will be the key driving force for product development.

First of all, fast paper has excellent mechanical strength, which enables it to maintain structural integrity and functionality in various harsh environments. Whether it is used to manufacture parts that need to withstand large loads or as a protective layer, fast paper can provide sufficient support to ensure long-term stable operation of equipment. For example, in the power system of new energy vehicles, fast paper can be used to make the protective shell of the battery pack, effectively resisting external impact and preventing damage to internal components. At the same time, the high strength characteristics of fast paper also make it suitable for manufacturing structural parts that require high load-bearing capacity, such as brackets, frames, etc. These applications not only improve the durability of the product, but also extend the service life of the equipment and reduce maintenance costs.

Secondly, the toughness of fast paper is also remarkable. Compared with traditional materials, fast paper has better tear resistance and is not easily broken or damaged by external forces. This feature is particularly suitable for applications that require frequent bending or folding. For example, in the design of automotive interior parts, fast paper can be used to make seat backs, dashboard covers and other parts, which not only ensures aesthetics but also improves user experience. In addition, fast paper has a large transverse elongation, which means that it can evenly distribute stress when stretched and avoid damage caused by local concentrated stress. This feature is particularly important for components that need to work in a dynamic environment because it can effectively reduce the risk of failure caused by fatigue damage.

Furthermore, the mechanical properties of fast paper are not only reflected in strength and toughness. Its longitudinal strength is greater than the transverse strength, which also provides optimization solutions for specific applications. In some cases, the material is required to have higher rigidity in one direction and a certain degree of flexibility in another direction. Fast paper just meets this demand. Through reasonable design, the material can perform optimally in different directions. For example, when manufacturing composite materials that require directional reinforcement, the anisotropic characteristics of fast paper can significantly improve the load-bearing capacity and stability of the overall structure without adding extra weight.

Not only that, fast paper also has good electrical insulation properties, which further enhances its application potential in the field of electrical safety. As electronic equipment becomes increasingly complex, the requirements for electrical insulation of materials are also getting higher and higher. Fast paper can not only effectively isolate current, but also prevent the potential dangers caused by static electricity accumulation. This is crucial to ensure the safety of operators and protect sensitive electronic components from damage. In the high-voltage circuit system of high-voltage electrical equipment and new energy vehicles, fast paper is widely used to manufacture key components such as insulating gaskets and partitions to ensure the electrical safety of the entire system.

In addition, the heat resistance of fast paper is also a highlight. In high-temperature environments, many traditional materials may soften, deform or even fail, while fast paper can maintain stable physical and chemical properties under extreme temperature conditions. This makes it very suitable for manufacturing components that need to be exposed to high temperature environments for a long time, such as heat shields in engine compartments and protective layers around exhaust pipes. In addition, fast paper also has excellent arc resistance and tracking resistance. These characteristics work together to ensure that the material can still work reliably when facing high voltage and strong current, greatly improving the safety of electrical systems.

It is worth mentioning that fast paper also performs well in environmental protection. As a recyclable material, fast paper has a low impact on the environment throughout its life cycle. With the increasing global attention to sustainable development, more and more companies are looking for green materials to replace traditional non-degradable or hazardous substances. The emergence of fast paper provides companies with an option that can meet high-performance requirements while taking into account environmental protection, helping to promote the industry to a greener and low-carbon direction.

Finally, in practical applications, fast paper has been widely recognized for its excellent comprehensive performance. Whether in the field of new energy or the automotive manufacturing industry, this material can provide reliable performance support. It not only improves the quality and reliability of products, but also helps companies achieve the goal of energy conservation and emission reduction. For companies pursuing efficient and environmentally friendly production methods, choosing high-quality fast paper is undoubtedly one of the best choices.

In summary, fast paper has become an ideal new material choice with its excellent mechanical strength and toughness. From high strength to good toughness, to excellent electrical insulation performance, every detail provides users with a more reliable, efficient and environmentally friendly solution. With the advancement and development of technology, fast paper in the future will continue to take solid steps in improving product performance and ensuring safe production, bringing more innovative solutions to various industries. In this process, continuous attention to user needs and technological innovation will be the key driving force for product development.