How does the use of asbestos-free gasket help improve the long-term reliability of industrial equipment?

Release Time : 2025-06-16

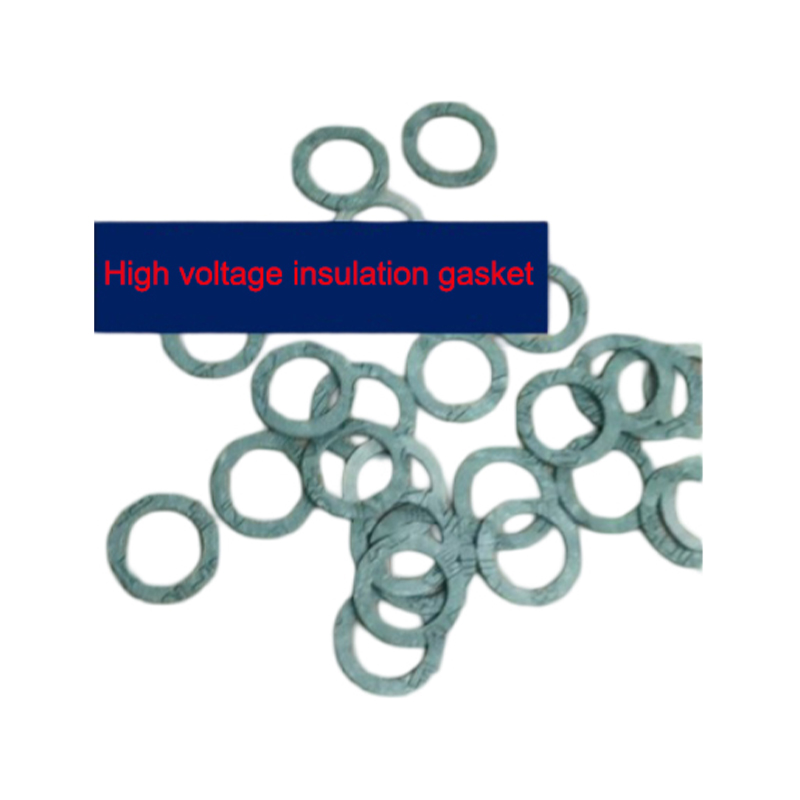

Over the past few decades, as the awareness of health and environmental impacts has deepened, asbestos materials have been gradually replaced by asbestos-free alternatives. Especially in the field of sealing applications, asbestos-free gasket has become an important choice for industrial equipment maintenance and upgrades due to its excellent performance.

1. Durability and anti-aging ability

Asbestos-free gaskets are usually made of high-performance fibers (such as aramid fibers, glass fibers, etc.) and other reinforcing materials, and are combined with special adhesives. These ingredients give quartz-free gaskets excellent durability and anti-aging ability. Compared with traditional asbestos gaskets, asbestos-free gaskets can maintain their physical properties without deformation or degradation over a wider temperature range. This means that even if they operate for a long time in high or low temperature environments, they can still provide reliable sealing effects, thereby reducing the risk of leakage caused by gasket failure and improving the overall reliability of the equipment.

2. Excellent chemical stability

Industrial environments are often exposed to various corrosive media, such as acid and alkali solutions, organic solvents, etc. Asbestos-free gasket has excellent chemical stability and can resist corrosion from most common chemicals. Whether it is strong acid or strong alkali, or even mixed media under certain special working conditions, asbestos-free gasket can effectively prevent damage caused by chemical reactions. This feature not only extends the service life of the gasket itself, but also protects the pipes, valves and other key components in contact with it from corrosion, ensuring the stable operation of the entire system.

3. Optimized mechanical strength

Asbestos-free gaskets are precisely designed and rigorously tested during the manufacturing process and have high mechanical strength. They can maintain good sealing performance under high pressure conditions without cracking or tearing. In addition, some high-level asbestos-free gaskets also have a self-sealing function, which can automatically adjust the shape to compensate for small gaps when subjected to pressure changes, further enhancing the sealing effect. This highly adaptable design makes asbestos-free gaskets particularly suitable for applications that need to withstand frequent pressure fluctuations, such as petrochemicals, power and other industries.

4. Reduce maintenance costs and downtime

Due to the excellent durability and reliability of asbestos-free gasket, enterprises can greatly reduce the need for regular inspection and replacement of gaskets. This not only saves money directly used to purchase new gaskets, but more importantly, reduces the indirect costs caused by removal, installation and commissioning. For example, in a chemical production line, if an unexpected shutdown due to gasket problems occurs, it may cause huge economic losses. The use of high-quality asbestos-free gaskets can effectively avoid this situation and ensure the continuous and efficient operation of the production line.

5. Promote environmental compliance

With the increasing global attention to environmental protection, many countries and regions have introduced strict laws and regulations to restrict the use of asbestos materials. As an environmentally friendly product, asbestos-free gasket fully complies with all relevant regulatory requirements currently and in the future. Using asbestos-free gasket can not only help companies comply with legal regulations, but also establish a good image of social responsibility, win customer trust and social recognition.

6. Improve operational safety

In addition to the above technical advantages, asbestos-free gasket also greatly improves operational safety. Asbestos materials were once considered ideal insulation and sealing materials, but because their fine fibers are easily suspended in the air and inhaled by people, they may cause serious respiratory diseases. In contrast, asbestos-free gasket does not contain any harmful substances, and will not release harmful particles to the human body during installation, maintenance, and even daily operation, providing a safer working environment for workers.

In summary, by choosing asbestos-free gasket, companies can not only obtain more durable sealing solutions, but also enjoy lower maintenance costs, higher production efficiency, and better environmental benefits. Faced with increasingly complex and changing industrial challenges, asbestos-free gasket is gradually becoming an indispensable part of various industrial facilities with its comprehensive technical advantages.

1. Durability and anti-aging ability

Asbestos-free gaskets are usually made of high-performance fibers (such as aramid fibers, glass fibers, etc.) and other reinforcing materials, and are combined with special adhesives. These ingredients give quartz-free gaskets excellent durability and anti-aging ability. Compared with traditional asbestos gaskets, asbestos-free gaskets can maintain their physical properties without deformation or degradation over a wider temperature range. This means that even if they operate for a long time in high or low temperature environments, they can still provide reliable sealing effects, thereby reducing the risk of leakage caused by gasket failure and improving the overall reliability of the equipment.

2. Excellent chemical stability

Industrial environments are often exposed to various corrosive media, such as acid and alkali solutions, organic solvents, etc. Asbestos-free gasket has excellent chemical stability and can resist corrosion from most common chemicals. Whether it is strong acid or strong alkali, or even mixed media under certain special working conditions, asbestos-free gasket can effectively prevent damage caused by chemical reactions. This feature not only extends the service life of the gasket itself, but also protects the pipes, valves and other key components in contact with it from corrosion, ensuring the stable operation of the entire system.

3. Optimized mechanical strength

Asbestos-free gaskets are precisely designed and rigorously tested during the manufacturing process and have high mechanical strength. They can maintain good sealing performance under high pressure conditions without cracking or tearing. In addition, some high-level asbestos-free gaskets also have a self-sealing function, which can automatically adjust the shape to compensate for small gaps when subjected to pressure changes, further enhancing the sealing effect. This highly adaptable design makes asbestos-free gaskets particularly suitable for applications that need to withstand frequent pressure fluctuations, such as petrochemicals, power and other industries.

4. Reduce maintenance costs and downtime

Due to the excellent durability and reliability of asbestos-free gasket, enterprises can greatly reduce the need for regular inspection and replacement of gaskets. This not only saves money directly used to purchase new gaskets, but more importantly, reduces the indirect costs caused by removal, installation and commissioning. For example, in a chemical production line, if an unexpected shutdown due to gasket problems occurs, it may cause huge economic losses. The use of high-quality asbestos-free gaskets can effectively avoid this situation and ensure the continuous and efficient operation of the production line.

5. Promote environmental compliance

With the increasing global attention to environmental protection, many countries and regions have introduced strict laws and regulations to restrict the use of asbestos materials. As an environmentally friendly product, asbestos-free gasket fully complies with all relevant regulatory requirements currently and in the future. Using asbestos-free gasket can not only help companies comply with legal regulations, but also establish a good image of social responsibility, win customer trust and social recognition.

6. Improve operational safety

In addition to the above technical advantages, asbestos-free gasket also greatly improves operational safety. Asbestos materials were once considered ideal insulation and sealing materials, but because their fine fibers are easily suspended in the air and inhaled by people, they may cause serious respiratory diseases. In contrast, asbestos-free gasket does not contain any harmful substances, and will not release harmful particles to the human body during installation, maintenance, and even daily operation, providing a safer working environment for workers.

In summary, by choosing asbestos-free gasket, companies can not only obtain more durable sealing solutions, but also enjoy lower maintenance costs, higher production efficiency, and better environmental benefits. Faced with increasingly complex and changing industrial challenges, asbestos-free gasket is gradually becoming an indispensable part of various industrial facilities with its comprehensive technical advantages.