Why is fast paper an ideal choice in the field of high-performance insulating materials?

Release Time : 2025-06-04

In the fields of electronics, electrical engineering, mechanical manufacturing, and industrial engineering, the requirements for insulating materials are increasing day by day. Not only do they need to have excellent electrical properties, but they also need to have good mechanical strength, heat resistance, and processing adaptability. As a special insulating material with excellent comprehensive performance, "fast paper" is widely used in transformers, motors, switchgear, capacitors and other electrical devices with its advantages of multiple colors, wide thickness range, outstanding mechanical and electrical properties, high heat resistance, and strong arc resistance. It has become an indispensable basic material for modern industry.

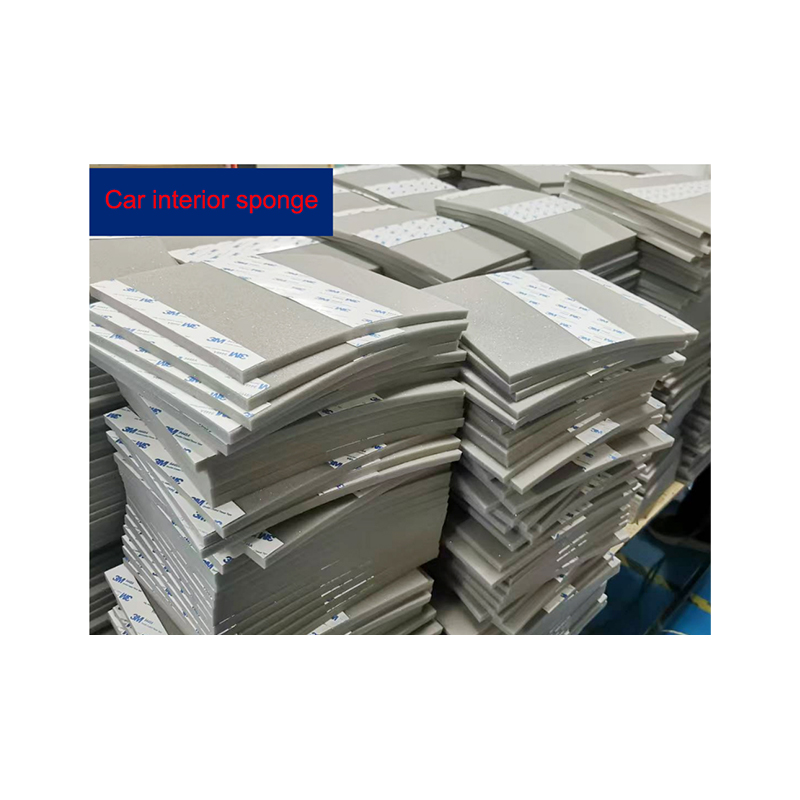

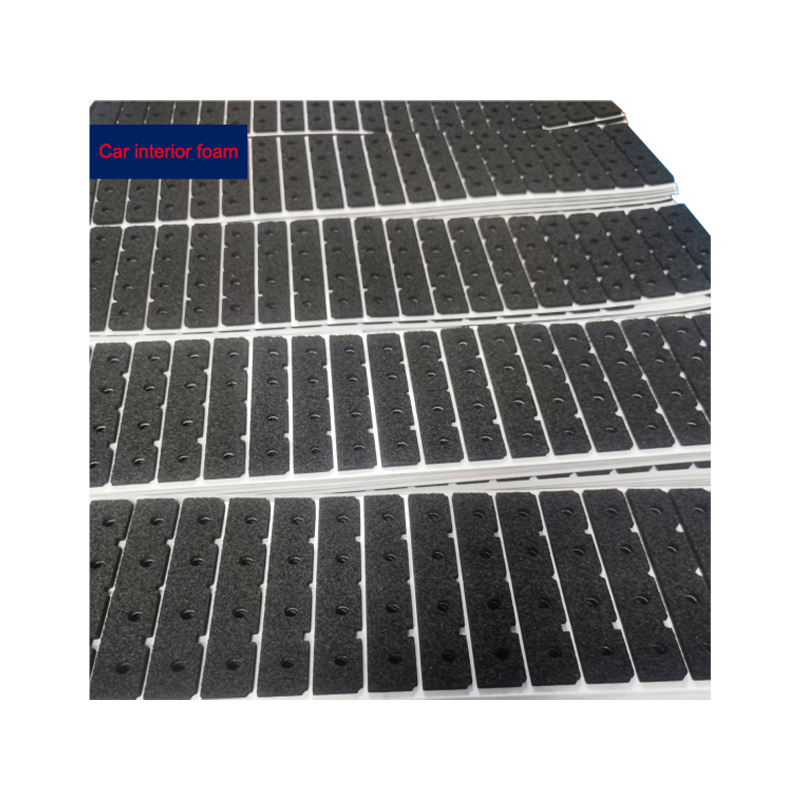

First of all, in terms of appearance and physical properties, fast paper shows extremely high practicality and flexibility. It provides a variety of color options such as red, white, gray and black, which is convenient for users to identify or match product design styles according to application scenarios. The thickness range covers 0.25mm to 2.4mm, meeting different needs from light and thin structures to high-strength supports. The material itself has excellent mechanical properties, high strength and good toughness, not easy to tear, longitudinal strength is better than transverse strength, and has a large transverse elongation, making it easy to bend and form but not easy to break, suitable for insulation isolation and protection in complex shape structures.

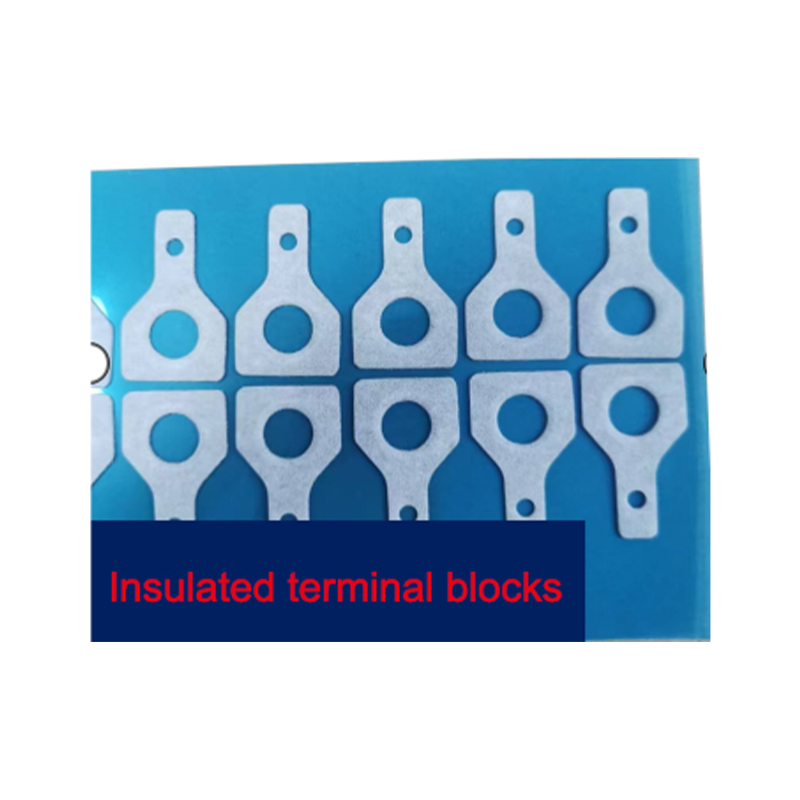

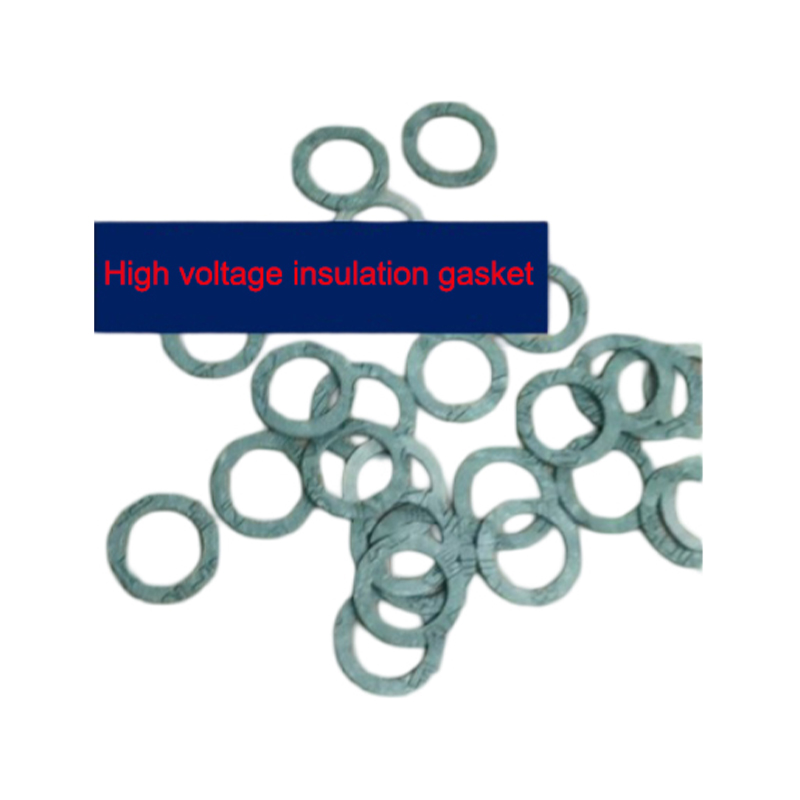

Secondly, fast paper is particularly outstanding in electrical performance. It has excellent electrical insulation performance, can effectively block the passage of current, and ensure the safe operation of equipment; at the same time, it has good anti-static ability, avoiding interference or safety hazards caused by static electricity accumulation, and is particularly suitable for insulation protection of high-precision electronic components and automatic control systems. Its resistance to leakage tracking reaches UL746A standard 600V or more, and it can maintain a stable insulation state even in a long-term high-voltage environment, preventing the occurrence of surface carbonization and breakdown.

In terms of heat resistance, fast paper also performs well. According to the electrical safety law standard, its Class A heat resistance level can reach 105℃, and its continuous service life exceeds 40,000 hours, which means that it can still maintain stable physical and chemical properties in a high temperature environment. According to the JIS K 6911 standard test, its short-term heat resistance is as high as 190°C (2 hours), showing excellent thermal stability and suitable for electrical insulation applications under various high-temperature conditions.

In addition, fast paper also has good arc resistance, with an arc resistance time of 120-140 seconds, far exceeding ordinary insulating materials. This feature is crucial to preventing instantaneous breakdown caused by high-voltage discharge, especially for power equipment such as circuit breakers and relays that may frequently generate arcs, providing additional safety guarantees for system operation.

It is worth mentioning that fast paper not only has stable performance, but also excellent processing performance. It can be processed in a variety of ways such as cutting, stamping, die-cutting, and hot pressing. It has strong adaptability and is widely used in the production and manufacturing of various electrical products. Whether as a core insulation layer in a laminated structure or as a local isolation material inside the equipment, it can play an excellent role.

In summary, fast paper has become an indispensable and important material in many high-end electrical equipment and precision instruments with its diverse color options, wide range of thickness applications, excellent mechanical and electrical properties, and excellent heat and arc resistance. It not only improves the safety and reliability of the product, but also brings greater freedom and possibilities to manufacturers in design and process implementation. Choosing fast paper means choosing an efficient, stable and trustworthy insulation solution.

First of all, in terms of appearance and physical properties, fast paper shows extremely high practicality and flexibility. It provides a variety of color options such as red, white, gray and black, which is convenient for users to identify or match product design styles according to application scenarios. The thickness range covers 0.25mm to 2.4mm, meeting different needs from light and thin structures to high-strength supports. The material itself has excellent mechanical properties, high strength and good toughness, not easy to tear, longitudinal strength is better than transverse strength, and has a large transverse elongation, making it easy to bend and form but not easy to break, suitable for insulation isolation and protection in complex shape structures.

Secondly, fast paper is particularly outstanding in electrical performance. It has excellent electrical insulation performance, can effectively block the passage of current, and ensure the safe operation of equipment; at the same time, it has good anti-static ability, avoiding interference or safety hazards caused by static electricity accumulation, and is particularly suitable for insulation protection of high-precision electronic components and automatic control systems. Its resistance to leakage tracking reaches UL746A standard 600V or more, and it can maintain a stable insulation state even in a long-term high-voltage environment, preventing the occurrence of surface carbonization and breakdown.

In terms of heat resistance, fast paper also performs well. According to the electrical safety law standard, its Class A heat resistance level can reach 105℃, and its continuous service life exceeds 40,000 hours, which means that it can still maintain stable physical and chemical properties in a high temperature environment. According to the JIS K 6911 standard test, its short-term heat resistance is as high as 190°C (2 hours), showing excellent thermal stability and suitable for electrical insulation applications under various high-temperature conditions.

In addition, fast paper also has good arc resistance, with an arc resistance time of 120-140 seconds, far exceeding ordinary insulating materials. This feature is crucial to preventing instantaneous breakdown caused by high-voltage discharge, especially for power equipment such as circuit breakers and relays that may frequently generate arcs, providing additional safety guarantees for system operation.

It is worth mentioning that fast paper not only has stable performance, but also excellent processing performance. It can be processed in a variety of ways such as cutting, stamping, die-cutting, and hot pressing. It has strong adaptability and is widely used in the production and manufacturing of various electrical products. Whether as a core insulation layer in a laminated structure or as a local isolation material inside the equipment, it can play an excellent role.

In summary, fast paper has become an indispensable and important material in many high-end electrical equipment and precision instruments with its diverse color options, wide range of thickness applications, excellent mechanical and electrical properties, and excellent heat and arc resistance. It not only improves the safety and reliability of the product, but also brings greater freedom and possibilities to manufacturers in design and process implementation. Choosing fast paper means choosing an efficient, stable and trustworthy insulation solution.